Vietnam Saigon Textile & Garment Industry/Fabric and Garment Accessories Expo 2018 took place from April 11 to 14 2018 at Saigon Exhibition and Convention Center (SECC), District 7, Hochiminh City.

Dap Vietnam Co., ltd joined this exhibition with our booth displaying the special machines such as DA 755S, DA 650-10, DA 670/680 and Beisler 550-5-5-2 that have the following detailed advantages:

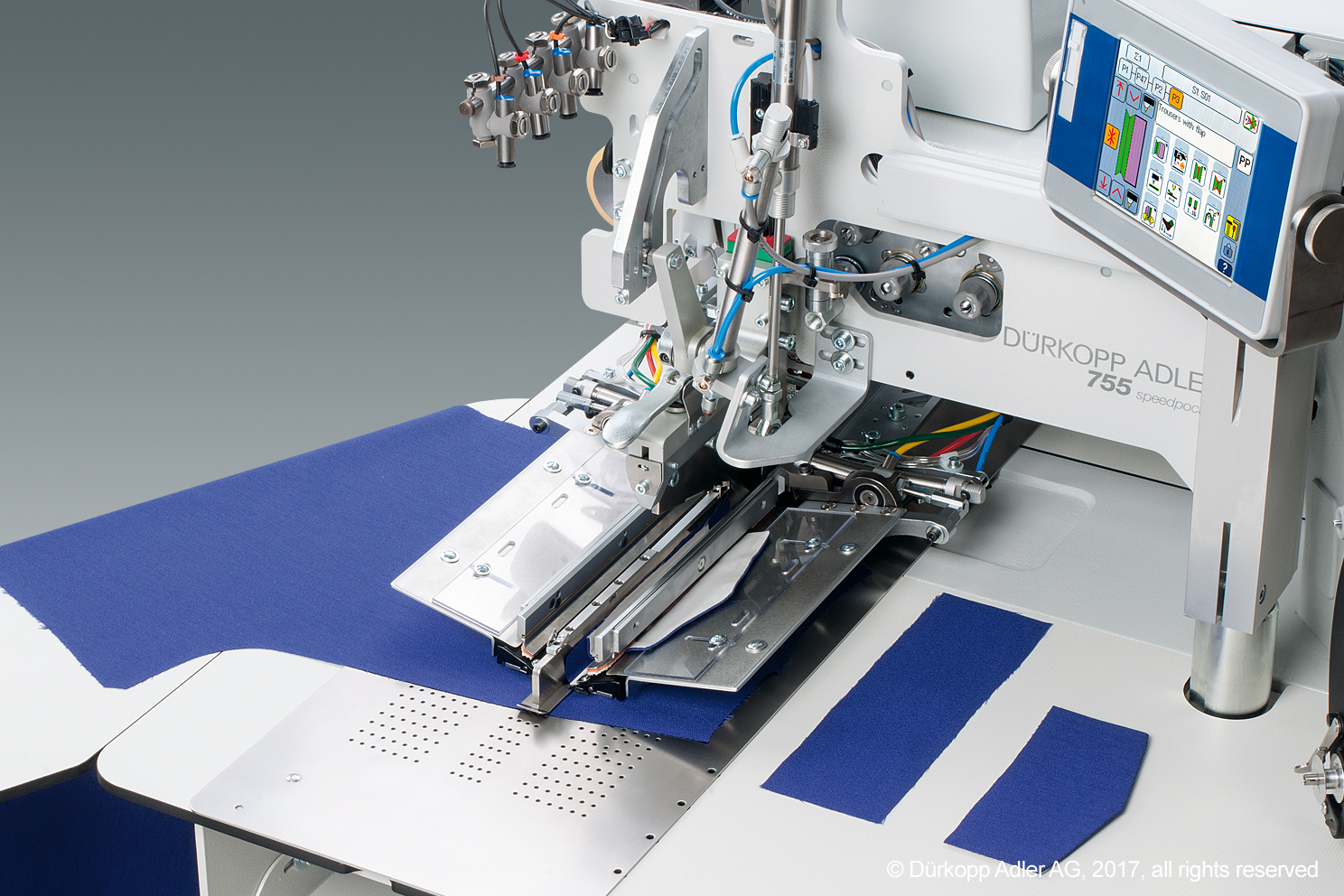

**DA755S SPEEDPOCKET-Sewing unit for runstitching of rectangular piped pockets, flap pockets and welt pockets

Innovative and powerful piping technology

The new generation of piped pockets is distinguished by its innovative technologies, powerful output and a modern design.

The DAC comfort control is integrated in the sewing machine with its high-resolution touch control panel OP7000 and gives the sewing unit outstanding performance parameters. The piped pocket machine is a must-have for every standardized production of rightangled piping, flap and welt-pockets.

The manual feeding of the additional parts in combination with optional equipment increases the performance of your production and raises the flexibility of the sewing unit.

Your advantages:

- Modern, reliable and network-capable Dürkopp Adler control technology, with high-resolution touch panel OP7000

- Touch panel with color graphic display for easy programming and fast access to all parameters – intuitive operating concept with freely configurable user interface,15 languages selectable

- Save the machine parameters in the machine ID

- Needle distances from 4,8 – 30 mm can be selected, short conversion time from one to the other needle distance (approx.30 min.)

- Stepper motor driven center blade drive with extended flexibility in material use due to increased material flow

- Large arm passage (335 mm) on the right hand side of the needle

- New folder concept as modular system

- Optimized folder lowering – for tension free folder movement onto the material

- Quick-release fastener for changing the folders without tools

- Quick-change connector (option) for quick replacement of heads with frequent needle distance changes

- Safe and clean winding of the thread when spooling with integrated bobbin winder with winding aid

- Fast color changing possible by separately driven bobbin winder (option)

- Maximum precision in the corner cuts due to easy-to- adjust corner knife station (option)

- Reduced bobbin change due to double bobbin volume with large vertical hook (Ø = 26 mm)

- High sewing safety thanks to needle thread and bobbin thread monitor in the standard of the sewing unit

- Flap scanning via photocell

- Processing of trousers pockets with extra wide piping strips up to 60 mm, with integrated blowing device (option) for the raising of the extra wide piping

- Pocket sizes from 20 – 240 mm selectable (depending on sewing equipment)

- Pressure monitor is included as standard

- UPS – uninterrupted power supply (option).

Performance example in 48 min.

Double piped pockets in hind trousers: approx. 2,200 –2,600 pockets

Single- or double piped pockets with flap in front jackets: approx. 1,300 – 1,600 pockets

**DA 650-10- Optimized work station for setting sleeves with “curve support”

Sleeve setting – highly simplified

Sleeve setting is one of the most difficult sewing operations in the clothing industry. The demands on the operator with regard to dexterity and knowledge of production technology are extremely high.

When using the sleeve setter 650-10 a large part of the diffi- cult handling is taken over by the machine by means of the “curve support” function. Sewing is simplified considerably, the training periods are shortened essentially and performance as well as quality are increased.

Your advantages

- Function “curve-support “ for easier handling specially in the sleeve head

- Finest fullness nuances via step motor-controlled belt transport to handle sleeve fullness even in most difficult fabrics

- Thread tension programmable per step, foot pressure and alternation for perfect seams independent of the material thickness, e.g. when processing epaulettes Programmable fullness values from -6 to +16

- Safety and efficiency due to the control box “DAC com- fort”

- Ergonomically designed work station for fatigue-free working with integrated LED sewing light and optimal view on the material to be processed

- Short training times due to easiest operation

- Easiest programming possible by ‘teach-in’ procedure and automatic mirroring for the second sleeve

- All functions are electronically controlled – no com- pressed air required

**DA 670/680- Optimized workstations for finishing armholes

The specialists for finishing armholes

The two postbed machines 670 and 680 perfectly round off the sleeve production. The 670 is ideal for attaching the sleeve lining and the sleeve head strips. The 680 allows the attaching and simultaneous trimming of the body lining and shoulder pads.

Both workstations are characterized by their ergonomically optimized workplace design. In the gripping area of the oper- ator, a 6-function key bar for quick access is located. The knee switch is used to call preseted modes for activating the stitch loosening, second stitch length and second foot stroke. The shaped table top offers maximum comfort of operation for the processing of large parts. For productions in shift work, the electrically height-adjustable stand set is recommended, which improves the ergonomics for different operators.

Your advantages:

- Programmable, automatic material thickness detection with two values within one shoulder pad

- Knee switch for manual activating the stitch loosening device, the 2nd stitch length and the 2nd foot stroke Switchable 2nd thread tension, 2nd foot stroke and 2nd stitch length for the adaptation of the machine to the different material thickness

- Secured sewing start with low thread tension by means of 2nd thread tension and stitch condensing

- Switchable fullness in the upper or lower material ply by push-button

- Intergrated 6-function key bar with ergonomically arranged favourite key for quick access

- Max. 9 mm stitch length (depending on the sewing equipment)

- Modern, reliable and network-capable Dürkopp Adler con- trol technology with “DAC classic”

- No manual greasing required – central minimum oil wick lubrication with warning light for oil deficiency (option) Large three-piece vertical hook (26 mm) with 60% higher bobbin thread capacity enables a reduced bobbin change Automatic winding aid for clean and safe bobbin winding Integrated LED light as standard

- Max. sewing speed of 1.800 stitches/min. (the maximum number of stitches depends on the use of the stitch loosening device)

- Automatically or manually switchable stitch loosening device for a “soft” shoulder pad

- Edge trimmer for perfectly trimmed excess lengths of lining and shoulder pads (only at 680)

- Slide-on table to improve the handling of the material Pneumatic sewing foot lift

**Beisler 550-5-5-2- Optimized workstation for stitching waistbands of

skirts and trousers

Comfortable stitching waistbands of trousers and skirts

The workstation Beisler 550-5-5-2, quipped with DAC classic control, offers a first-class solution for stitching waistbands of skirts and trousers in seam shadow or stitching on the waistband.

The combination of bottom, needle and top puller feed and a sewing equipment specially developed for this operation sequence, makes it possible to process waistbands accurately and true to shape. The ergonomically shaped table and the rest table allow unhindered handling of the material.

Your advantages:

-Modern, reliable and network-capable Dürkopp Adler control technology, incl.control panel OP1000 with numerical display

The special designed shaped table allows perfectly fitting waistband processing

-Ergonomically shaped table top guarantees unhindered handling

Flat, pucker-free seams due to needle feed and top puller feed

-Perfect transport feeding due to intermitted working top puller feed

-Sewing equipment with positively controlled compensating foot and springmounted guide for accurate sewing in the seam shadow

-Optional compensating foot for topstitching through the waistband with flexible use e.g. for ladies’ trousers and skirts

-Foot stroke level adjustment guarantees trouble-free climbing over transversal seams and belt loops, even when processing large material thicknesses

-Stitching straigth or curved waistbands of skirts and trousers with optimized sewing foot for an even more narrow stitching in the seam shadow of the waistband edge

-Topstitching of straight or curved waistbands with a margin of 1,6 mm (optional hinged compensating foot: 0274 006834) on the left hand side of the waistband

Those are all information about our industrial sewing machines introduced at this exhibition: Vietnam Saigon Textile & Garment Industry/Fabric and Garment Accessories Expo 2018

DAP Vietnam Co., Ltd. is the official representative for Shanggong group with its famous brands such as DÜRKOPP ADLER, PFAFF, CKSL, SGGEMSY, MAUSER and RICHPEACE. They have been being well-known brands in the garment industry for over 150 years.

We are responsible for providing, having a warranty and repairing sewing machines such as DÜRKOPP ADLER, PFAFF, CKSL, SGGEMSY, MAUSER and RICHPEACE in Vietnam and South East Asia for the following industries: Footwear industry and leather industry; Garment industry; Textile at home; Seat cushion industry; Sportswear and outdoor apparel industry; Textile engineering; Automobile interior