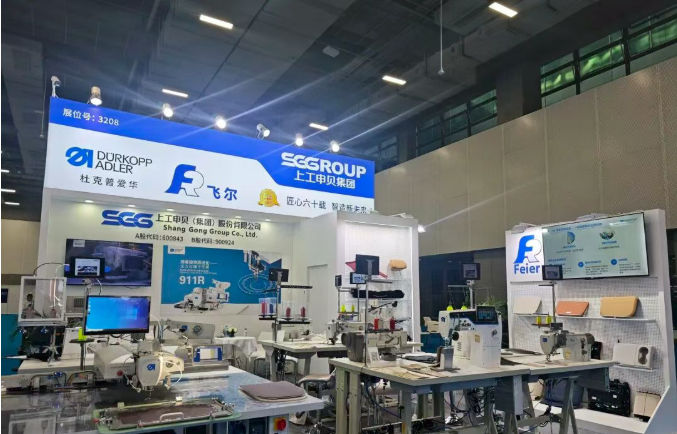

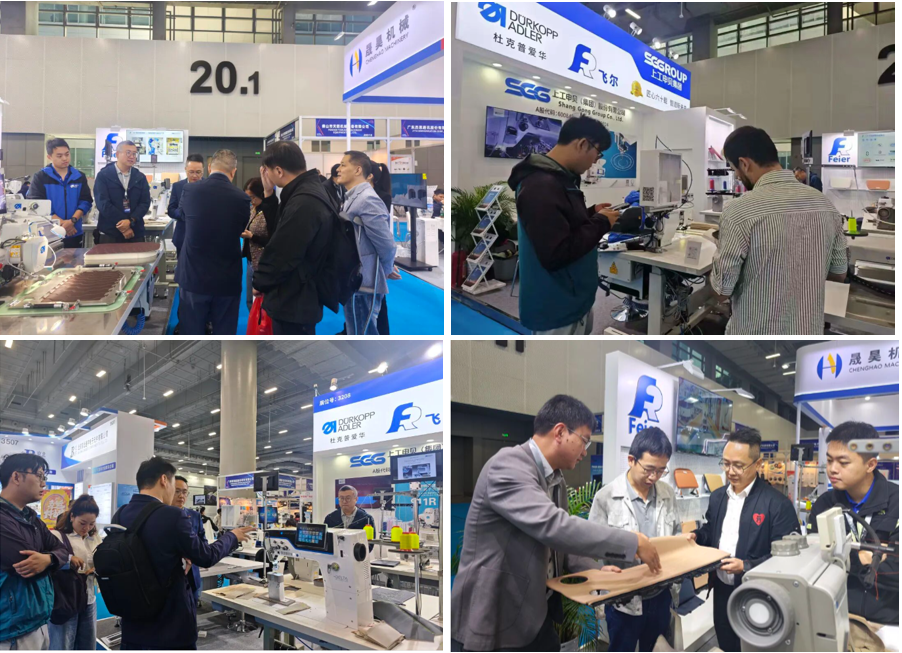

Held from November 21 to 24, 2025, the Guangzhou International Automotive Technology Exhibition saw the German brand Dürkopp Adler, with a history of more than 165 years and a member of the ShangGong Group, jointly exhibiting with ShangGong Feiler Automotive Components at Booth 20.1. They showcased a range of innovative industrial sewing solutions for automotive manufacturing, fully demonstrating their outstanding engineering capabilities and deep technological expertise in automotive safety systems and high-end interior sewing processes.

The 550-D800 seat side airbag seam sewing workstation, based on the modular M-TYPE DELTA platform, integrates functions such as automatic material thickness detection, active electronic thread tension control, real-time stitch skip monitoring, and neat start-of-seam formation. These features ensure that the tear seam remains strong and reliable under normal operating conditions and tears precisely along the preset path in the event of a collision. All sewing parameters and operating data are automatically collected, stored, and traceable, fully meeting the stringent requirements of the automotive industry for functional safety and process compliance.

As a trusted partner to the global automotive manufacturing industry, Dürkopp Adler has accumulated extensive technical know-how and practical experience in sewing and welding applications for seats, airbags, and interior components. After on-site demonstrations, technical experts from numerous OEMs and Tier 1 suppliers highly praised Dürkopp Adler for its low failure rate, high cycle efficiency, and long-term operational stability.

As the automotive industry accelerates toward electrification, intelligence, and premiumization, the increasing demands for high reliability in safety systems and uniqueness in interior design continue to raise the bar for sewing technology. Dürkopp Adler will remain customer-centric and adhere to rigorous standards to provide global automotive customers with reliable, high-quality solutions, helping them move forward steadily in safety, efficiency, and compliance.