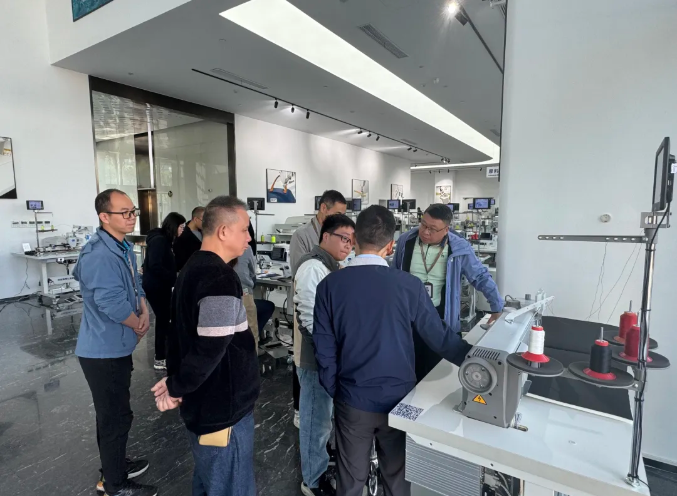

On November 14, Mr. Liu Changchuan, General Manager of Kuka Home’s Lean Operations Center, and Mr. Zhang Liwei, Head of the Intelligent Manufacturing Equipment Service Department, led a delegation to the headquarters of the ShangGong Group to attend the Dürkopp Sofa Lean Production Technology Exchange Conference. They were warmly received by Mr. Li Xiaofeng, Executive Vice President of ShangGong Group and General Manager of the Sewing Machine Division, Mr. Wu Weijie, Board Secretary and General Manager of Dürkopp Shanghai, as well as Dürkopp Adler product experts from Germany, Michael Grundmann and Thomas Maleska. The two sides engaged in in-depth, face-to-face discussions on processes, efficiency, and future development.

The exchange focused closely on Kuka Home’s actual production scenarios. From the classic and reliable M-TYPE mechanical platform, the cutting-edge QONDAC + DAISY digital system, to precise presser-foot requirements and real-time fabric monitoring, Dürkopp’s equipment selection and functional configuration are highly aligned with the rhythm of factory production lines, quality standards, and upgrade objectives. This provides comprehensive support for Kuka’s advancement toward lean and digitalized production management. Such deep customization capabilities demonstrate Dürkopp’s strong technological barriers and irreplaceable position in the field of upholstered sewing, and truly fulfill its promise of “understanding processes and understanding customers even better.”

Every equipment upgrade represents a firm pursuit of higher efficiency, more stable quality, and stronger delivery reliability. Facing the vast overseas markets, Dürkopp continues to accompany Kuka on its steady journey forward, helping Chinese sofa manufacturing achieve greater precision, supporting national brands in going further, and showcasing on the global stage the reliability and excellence of China’s intelligent manufacturing.

With profound industry expertise and forward-looking technological strategies, Dürkopp will continue to take customer pain points as the starting point for innovation, embedding R&D deeply into real production scenarios. Each technological iteration will precisely address practical needs, striving to create tangible value for users—so that every investment is transformed into measurable efficiency gains, reliable quality assurance, and sustainable competitive advantages.